Installation of the intercalated staircase – instructions for implementation

Correct installation of prefabricated interlocking stairs requires precise preparation of supports, accurate alignment of the geometry of the interlocking, and ensuring stability during installation work. The process is carried out using a crane with the appropriate capacity and overhang. The prefabricated system allows rapid installation of the entire staircase in a few days.

Preparation of support sites

Before the installation of concrete interval stairs, a check is made on the dimensions and levels of the supports. The resting beams or wall supports must reach min. 70% of the design strength. Support surfaces leveled with low-shrinkage mortar with an accuracy of ±5 mm.

For modular procedure stairs, sockets are prepared in the walls of the staircase. Depth of embedment min. 120 mm for steps, 150 mm for cheek beams. Elastomeric pads 10-20 mm thick distribute pressure.

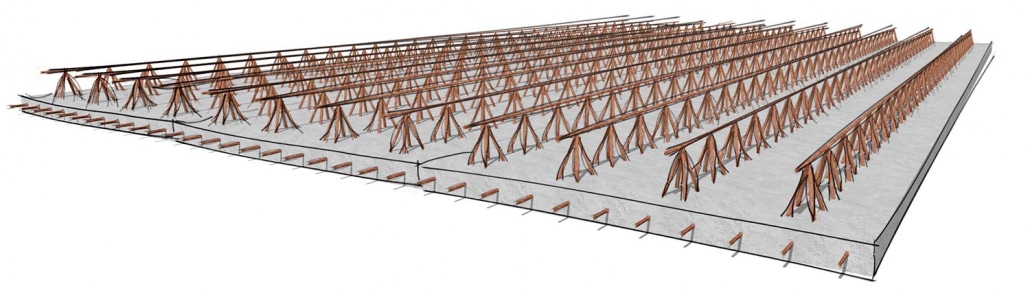

Internal transport and lifting

Elements how to lay out the staircase of the procedure indicate the points of slings for balance. Treads lifted in the installation position with traverses or chain slings. Sling opening angle max 60° to avoid excessive compressive forces.

The system calculator of the staircase procedure determines the weight of the elements: 80-120 kg/modular tread, 1500-3500 kg/monolithic run. Minimum lifting capacity with a 20% margin. Lifting speed of max 2 m/min with intervening elements.

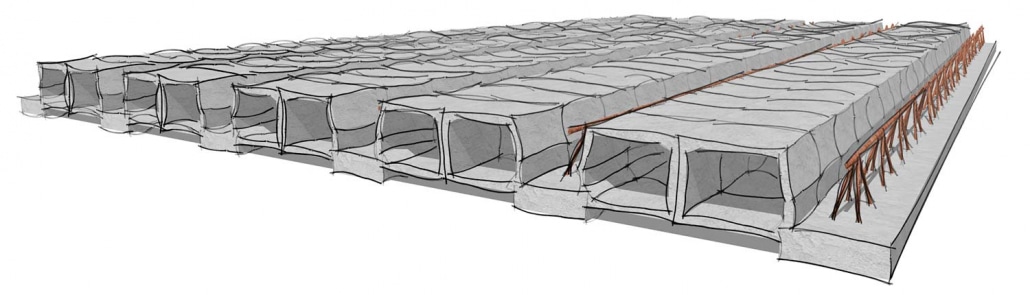

Embedding of treatment gears

Installation of self-supporting procedure stairs begins with the lower flight with precise setting of the angle of the procedure. Geometry control with templates and geodetic measurements. Adjustment tolerance ±5 mm horizontally, ±10 mm vertically.

Successive flights of stairs with a tread rest assembled with the continuity of the line of the flight. The width of the joints between the elements 10-20 mm filled with shrinkage-free mortar. Control of the usable width of the steps in the treatment zone.

Assembly of modular steps

In the system of millwork staircase procedure individual steps arranged from bottom to top. Each step leveled individually with height control. Temporary stabilization with stamps until mortar sets.

Wedge treads of modern treatment stairs require special precision in installation. Preservation of the radius of the treatment controlled by an arch template. Equal distribution of steps in the treatment area for user comfort.

Making structural connections

Connecting reinforcement in how to calculate the stairs of the procedure according to the project – bars φ12-16 mm in sockets. Pouring the joints with C30/37 concrete or expansive mortar. Vibrating for accurate filling of all spaces.

Expansion joints between the treads and the walls of the procedure stairs dimensions 10-20 mm filled with elastic material. Stainless steel expansion profiles on the edges of the steps. The system compensates for thermal deformation and building settlement.

Installation of railings and handrails

After the installation of how to make a staircase of the procedure, system or individual balustrades are installed. Chemical anchors M12-M16 in prefabricated holes or drilled on site. The height of the railing 90-110 cm according to the regulations.

In the treatment area of the treatment stairs, the handrail led smoothly in an arc. Balustrade posts spaced evenly every 10-12 cm for the safety of children. Inner handrail at the wall at a height of 90 cm.

Quality control of the assembly

Acceptance of concrete interval stairs includes: checking the geometry (width of the steps on the running line ±5 mm), checking the height of the steps (±3 mm), measuring the radius of the procedure (±10 mm), verifying the verticality and levels.

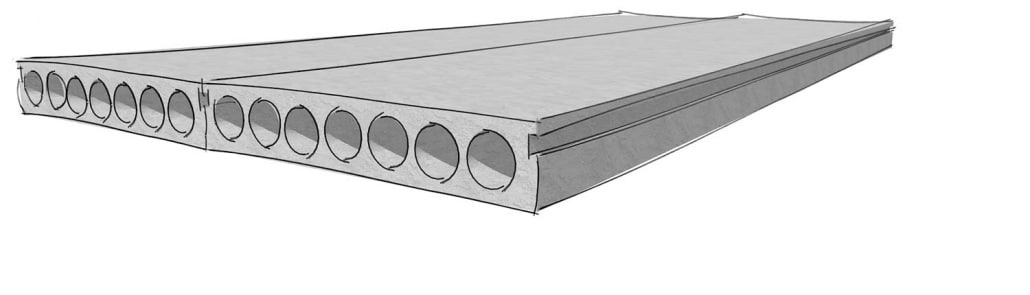

Load test of modular procedure stairs with a test load of 5 kN/m² for 24 hours. Measurement of deflections must not exceed L/250. Visual inspection of the formation of cracks. Checking the patency of drains and expansion joints.

Finishing work

Surfaces of self-supporting procedure stairs prepared for laying cladding or painting. Replenish cavities and irregularities with joint compound. Priming with preparations that increase adhesion.

Finishing of interval stairs with a tread can include: stone or ceramic cladding with adhesive, non-slip resin flooring, ground terrazzo, painting with concrete paints. Marking the edges of the steps with a contrasting color.