Precast concrete price list – comprehensive calculation of precast elements

Precast concrete price list is shaped by many factors that affect the final cost of precast elements. Pricing includes the cost of materials, production, transportation, installation and any additional work. Precast concrete price depends on the type of element, dimensions, concrete class, degree of reinforcement and size of the order.

Cost components of prefabricated products

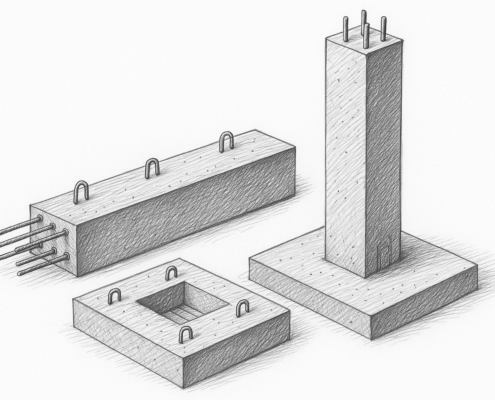

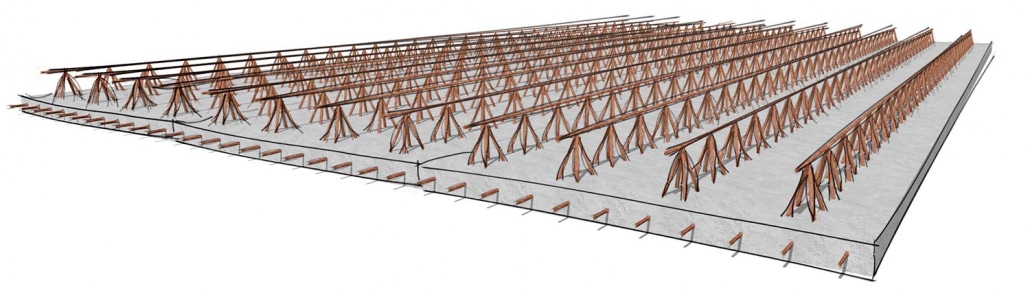

The main element affecting the prefabricated price is the cost of raw materials, which accounts for 40-50% of the value of the product. Cement, aggregates, reinforcing steel and admixtures are the main cost components. Precast reinforced concrete price increases in proportion to the degree of reinforcement – from 60 kg/m³ for lightly reinforced to 200 kg/m³ for heavily reinforced elements.

Concrete element production costs include: mold depreciation (10-15%), energy (5-10%), labor (15-20%), factory overhead (10-15%). Transportation accounts for 5-15% of the price, depending on distance and dimensions. Assembly is an additional 20-30% for structural components.

Price list 2024 for precast concrete products

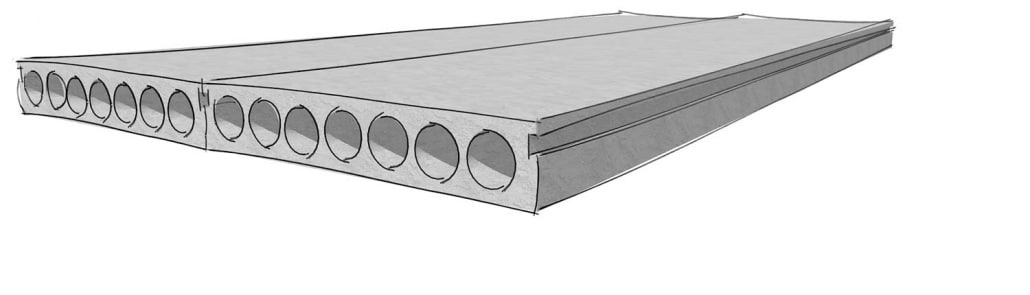

In 2024, prices are seen stabilizing after previous increases. Precast elements price in 2024 per m³ of concrete ranges from PLN 800 for simple elements to PLN 2500 for prestressed structures. Precast concrete in the summer season 2024 more expensive by 5-10% due to the construction peak.

Current rates in 2024 show that precast concrete manufacturers offer discounts of 10-15% for orders over 100 m³. Precast concrete fence components in 2024 – posts 80-150 zl/m³, spans 200-400 zl/m³. Structural elements: beams 1200-2000 zł/m³, posts 1000-1800 zł/m³, slabs 400-800 zł/m³.

Price forecast for 2025

Projections for 2025 indicate a price increase of 4-7% for standard precast products. Precast concrete wall price in 2025 will depend on the cost of energy used in production. New environmental standards may raise costs by an additional 3-5% due to CO₂ reduction requirements.

In 2025, CEM II and CEM III low-carbon concretes are expected to become widespread, and may be 5-10% cheaper. Precast concrete pricing in 2025 will take into account the increasing share of automation reducing labor costs. Developments in 3D printing technology may introduce a new pricing category for non-standard elements.

Cost comparison of different types of prefabricated products

Price analysis shows significant differentiation: small-size prefabricated elements (blocks, hollow blocks) PLN 3-15/unit, medium-size prefabricated elements (slabs, beams) PLN 200-1000/unit, large-size prefabricated elements (walls, ceilings) PLN 2000-10000/unit. Catalog elements 30-40% cheaper than custom-made ones.

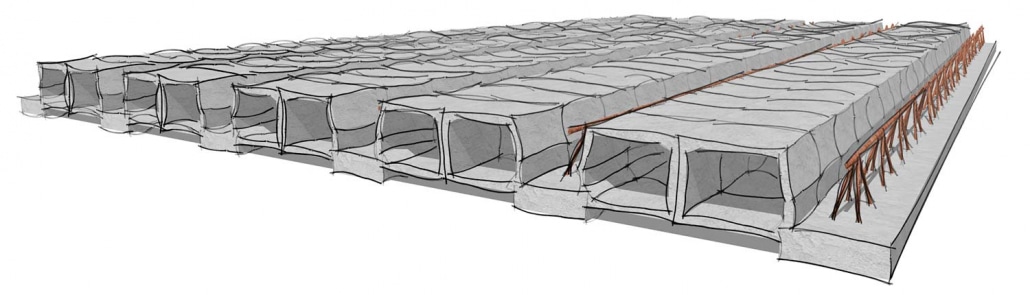

Comparing technologies: traditional precast concrete cheapest, architectural concrete more expensive by 50-70%, prestressed concrete by 100-150%. Self-compacting concrete precast more expensive by 20-30% but offers better surface quality. Textured elements (washed, sandblasted) with a surcharge of PLN 30-50/m².

Optimization of prefabrication costs

Reduction of precast concrete costs possible by: use of typical elements from the catalog, grouping of orders, own collection from the plant. Designing with a 60 cm module minimizes cutting. Winter orders (November-February) cheaper by 10-15%.

Savings on concrete elements price by choosing the optimal concrete grade – the highest is not always necessary. Rational reinforcement according to actual loads. Giving up decorative finishes where they are not visible.

Operating costs and life cycle

Investment in prefabricated elements price higher initially pays for itself through minimal maintenance. Maintenance costs 0.1-0.3% of value per year. Durability of 100 years means lowest cost per year of use among all technologies.

The precast concrete system total life-cycle price takes into account: no structural repairs, energy efficiency due to thermal mass, adaptability and expandability. The residual value after 50 years is 30-40% of the initial price. Elements are recyclable as aggregate.

Comprehensive pricing of precast concrete manufacturers should take into account not only the purchase price but the total cost of implementation. Professional consulting allows you to optimize the selection of elements. Cost simulations of various variants facilitate the investment decision.

The final precast concrete price list for each project requires an individual calculation that takes into account the specifics of the site, construction location and delivery schedule. We encourage you to contact us to prepare a detailed precast offer tailored to your investment.