Key advantages of prefabricated balconies

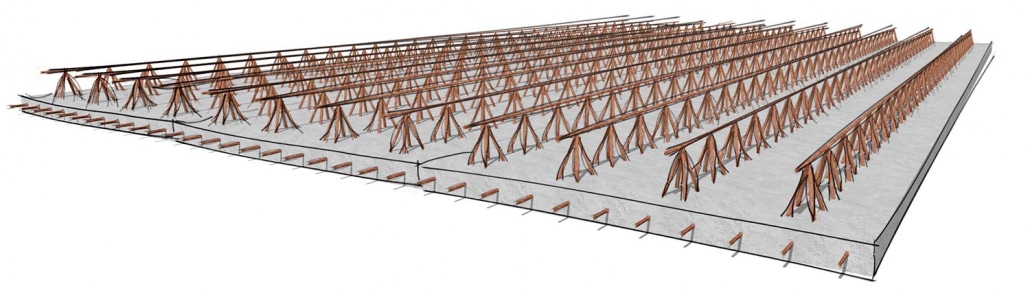

Prefabricated balconies – eliminating thermal bridges

Prefabricated balconies with thermal insulation connectors completely break the thermal bridge. The Isokorb or similar system reduces heat loss by 80-90% relative to a traditional joint. The heat transfer coefficient at the joint Ψ ≤ 0.20 W/mK. Eliminates the risk of condensation and mold in apartments next to the balcony. Heating savings of 5-10% for the entire building.

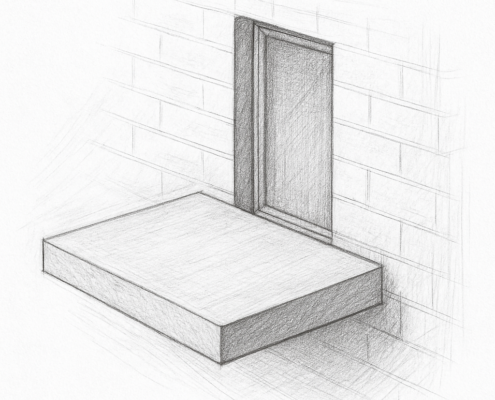

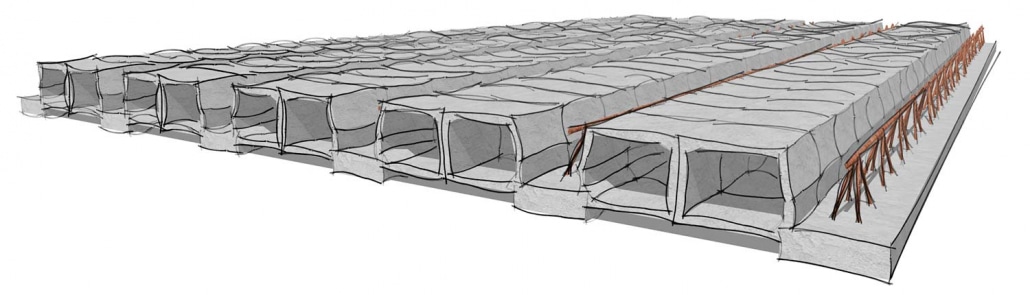

Instant assembly of finished components

Installation of prefabricated balconies takes 20-30 minutes per element. A prefabricated balcony delivered as a finished product does not require formwork. Elimination of concreting and setting time speeds up construction by 3-4 weeks. In addition, the possibility of installation in all weather conditions. Immediate full load-bearing capacity after installation.

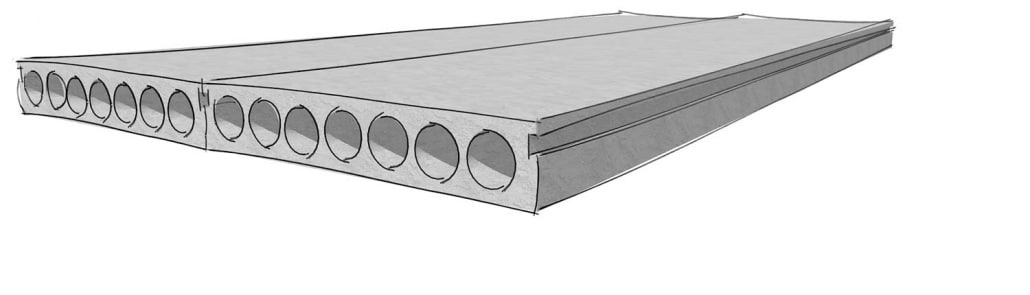

Perfect workmanship

Prefabricated balconies manufactured in halls provide tolerances of ±3 mm. The perfectly smooth surface does not require leveling before laying the floor. The prefabricated balcony has precise slopes and properly executed drips. Subsequently, there are no flares, cracks or irregularities typical of on-site concreting. Quality unattainable with traditional methods.

Prefabricated balconies – durability for decades

Precast balcony made of C35/45 concrete guarantees a minimum of 50 years of trouble-free service. Exposure class XC4, XF4 ensures resistance to frost and salt. Precast balconies do not require repairs for the first 25-30 years. In addition, the thick lagging protects the reinforcement from corrosion. Invest in a maintenance-free solution.

Reduction in total costs

Despite the higher initial price, prefabricated balconies are cheaper over their life cycle. Elimination of system formwork saves 30-40% of labor costs. A prefabricated balcony does not generate material losses on site. In addition, the absence of thermal bridges reduces heating costs. Return on investment within 5-7 years of operation.

Architectural uniformity of the facade

Prefabricated bal conies provide an identical appearance for all balconies on the facade. Repeatability of dimensions and details creates a harmonious composition. Prefabricated balcony eliminates execution errors spoiling aesthetics. However, the possibility of individual design of shapes. Increase the value of the property through quality workmanship.

Prefabricated balconies – structural safety

Prefabricated balcony factory tested for a load of 5.0 kN/m². Quality control of each element before delivery to the construction site. Prefabricated balconies have certificates and static calculations. Then eliminating the risk of construction errors. System proven in thousands of implementations.

Opportunities for individualization

The system of prefabricated balconies allows any shape and size. Straight balconies, arched balconies, corner balconies according to architectural design. Prefabricated balcony can have integrated flower pots or seats. In addition, a variety of finishes and surface textures. Design flexibility while maintaining the advantages of prefabrication.