Prefabricated ceiling price

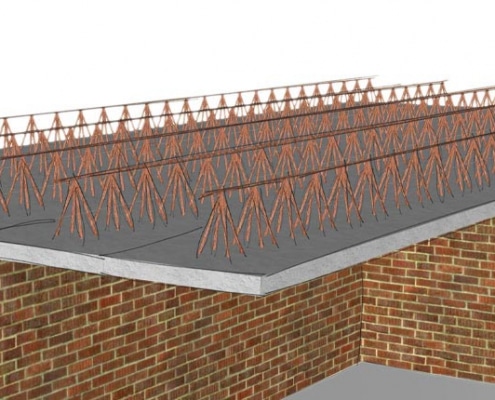

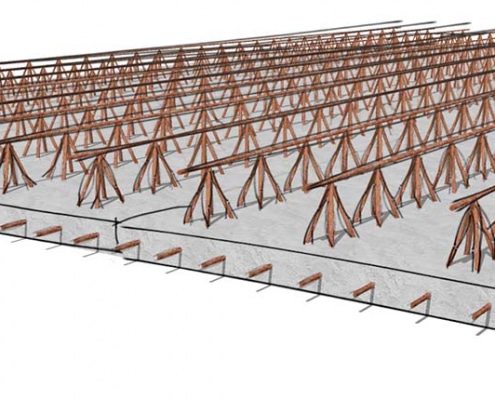

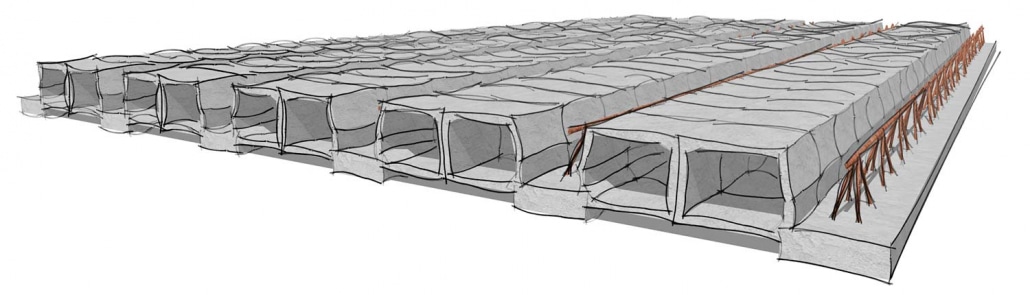

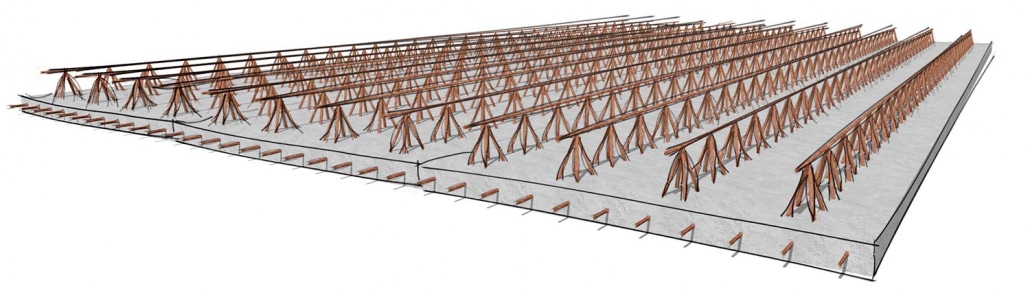

A comprehensive analysis of the prefabricated ceiling price requires consideration of all cost components, not just the price of the prefabricated elements themselves. For the most popular Teriva system, the cost of materials is indicatively: prefabricated beams 42-52 zlotys/mb, ceiling blocks 4-10 zlotys/piece (8.33 pcs/m²), additional reinforcement and overcrete 40-55 zlotys/m². The total cost of materials is approximately 175-265 zlotys per square meter, to which must be added transport 10-18 zlotys/m² and installation 40-60 zlotys/m². The final price of making a Teriva floor is therefore indicatively 225-343 zlotys per square meter.

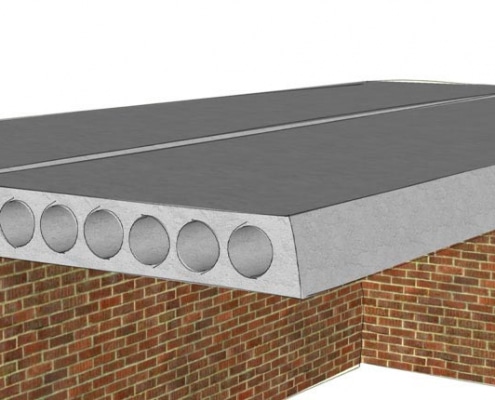

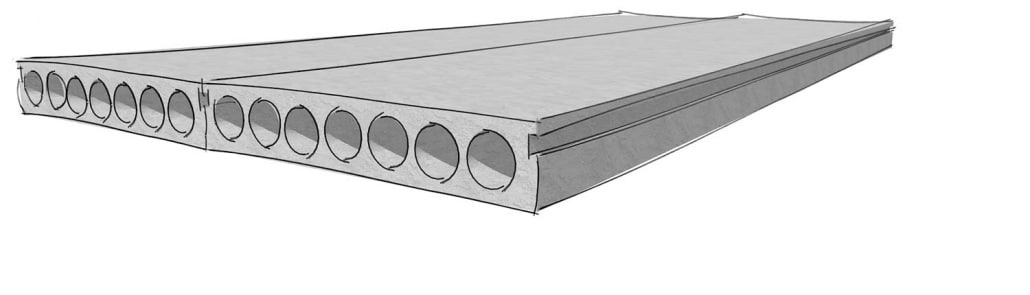

The hollow core slab system presents itself differently – the higher unit cost of the elements (indicatively 140-220 PLN/m² for slabs with a load capacity of 5 kN/m² and a span of 6m) is compensated for by the lack of additional materials and minimal labor intensity of installation. After taking into account specialized transportation (PLN 15-25/m²) and crane installation (PLN 25-35/m²), the total cost is indicatively PLN 180-280 per square meter. This price is particularly competitive for spans over 6 meters, where alternative solutions would require expensive beams or joists.

Cost comparison with traditional technology

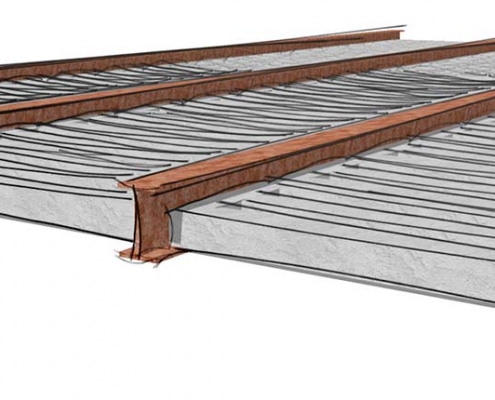

Juxtaposing the prefabricated ceiling price per m2 with the cost of a monolithic ceiling reveals hidden savings. Monolithic reinforced concrete floor with a thickness of 18 cm costs approximately: system formwork rental 35-50 PLN/m²/month, steel reinforcement 120-150 PLN/m², concrete 70-85 PLN/m², labor 80-120 PLN/m². The sum of 305-405 PLN/m² does not include indirect costs – the extension of scaffolding rental by 3 weeks (additional 15-20 PLN/m²), crane service for concrete feeding (8-12 PLN/m²) or material losses of up to 5-8%.

The key difference emerges when considering the cost of construction financing. Shortening the execution by one month for a construction loan of PLN 500,000 and an interest rate of 7% means saving about PLN 2,900 on interest alone. Faster commissioning of the building for commercial investments translates into earlier rental income – for a 1,000 sqm office building, this is an additional approximate 50,000-80,000 zlotys of income per month.

Cost optimization with different types of projects

The economics of prefabricated ceilings change significantly depending on the scale and nature of the project. In single-family housing, where the floor area is 100-200 m², the cost of transportation and crane can increase the unit price by 15-20%. However, the possibility of self-assembly of lightweight Teriva-type elements by a 2-3-person team without a crane compensates for these additional costs. When buying directly from the manufacturer, you can get discounts of 5-8% and free transportation for orders above a certain value.

In large-scale projects – housing estates or industrial halls – where the floor area exceeds 5,000 m², economies of scale work in favor of prefabricated elements. Negotiated discounts reach 12-18%, transportation costs are spread over a larger number of elements (dropping to PLN 5-8/m²), and specialized assembly crews reach a capacity of 300-400 m² per day. Standardization of elements throughout the project further reduces production costs by 8-10%. For a developer developing a 10,000 sqm PUM estate, the use of prefabricated elements can reduce construction costs by an indicative 400,000-600,000 zlotys while shortening construction by 2-3 months.